What is the Direct Role of Analytics in Supply Chain Management?

Table of Contents

- jaro education

- 16, February 2023

- 2:40 am

Today, the role of data analytics in supply chain management is intertwined and both share a direct relationship. If you want to build a career in supply chain data analytics then you are at the right place as this blog has an inside-out overview of supply chain data analytics and the importance of data analytics in supply chain management.

What is Supply Chain Data Analytics?

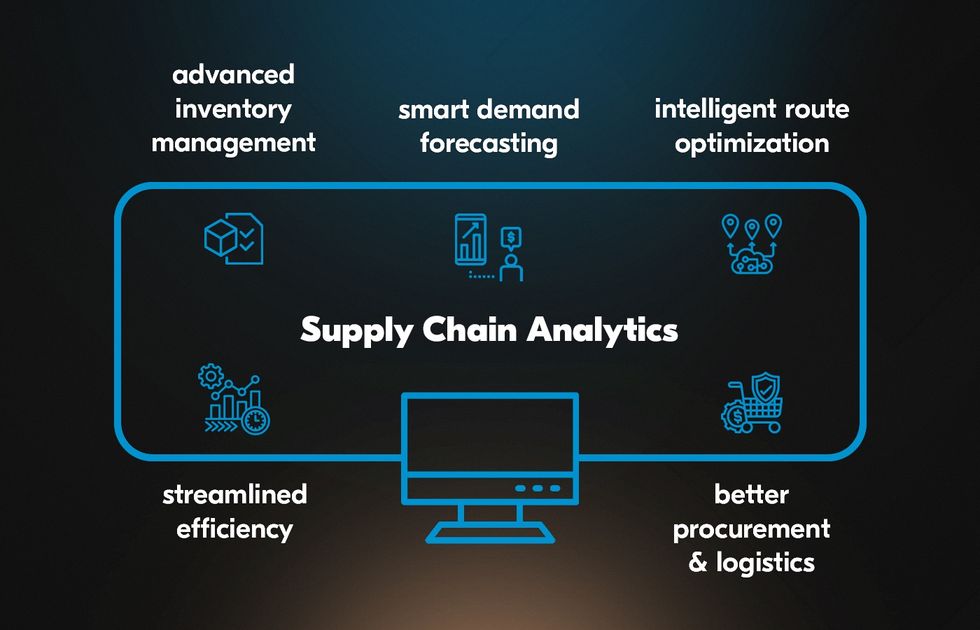

Supply chains generate huge data and supply chain data analytics acts as a bridge between the data and its rightful use for corporations for strategic decision-making. The insights grabbed from the data can help organizations improve the quality, delivery, and customer experience which impacts overall profitability.

*acropolium.com

Take the example of India’s quick commerce platform Zepto whose supply chain is so efficient that it can deliver anything to everything within 10 minutes. But to reach this level of efficiency, they have spent a lot of time and money on R&D and supply chain data analytics.

Be it a quick commerce platform, a D2C brand, or any organization, the need and importance of data analytics in supply chain management is huge and one shouldn’t ignore the power of data, and the benefits of gaining insights from the data acquired. Having said that, let’s explore various types of supply chain data analytics.

6 Types of Supply Chain Data Analytics That Organizations Rely On

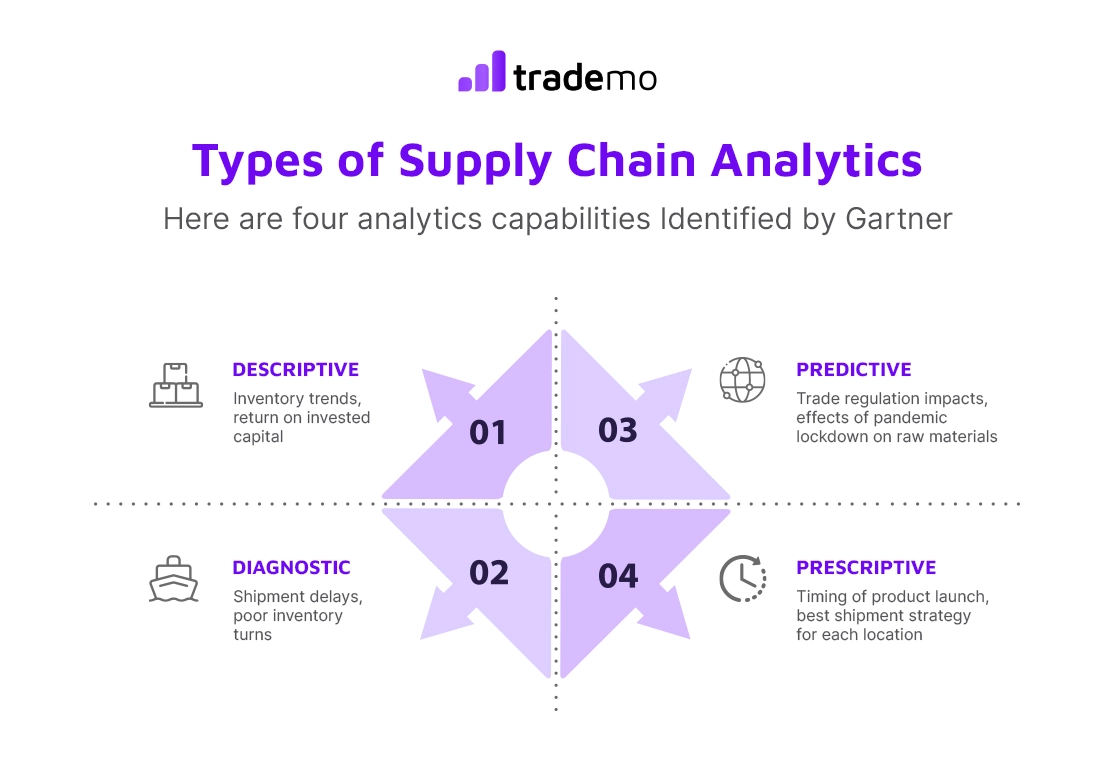

While the supply chain represents the ability to move goods from the warehouse to the customer’s house, analytics represents the ability to make data-driven decisions based on visualization tools, graphs, charts, and other means. Here are 4 types of supply chain data analytics that corporates rely on –

*res.cloudinary.com

1. Descriptive Analytics

It is the process of turning data into insights. It helps organizations make strategic decisions by providing a clear picture of the past to make futuristic decisions. Descriptive data analytics in the supply chain is important for leaders to understand their competitive environment. It enables the company to comprehend its market positions and identify areas for improvement. Here are some use-case examples of descriptive analytics in SCM:

- Key customers.

- Key products.

- Customer-Product Matrix.

- Coefficient of Variation.

- Average Demand Interval.

- Customers per SKUs.

- Volume Variability Matrix.

- Forecast Error.

2. Predictive Analytics

This side of supply chain data analytics helps organizations understand the various outcomes or future scenarios and their business implications. Predictive analytics leverage statistical algorithms, and machine learning techniques to identify the likelihood of future outcomes. For example, an apparel store can prepare for the upcoming summer by using predictive analytics to identify products most likely to grab higher sales.

3. Prescriptive Analytics

This type of supply chain data analytics optimizes decision-making by providing recommended actions based on insights gained from descriptive, diagnostic, and predictive data analytics. Prescriptive data analytics in supply chain management helps you answer the following questions –

- What do customers want?

- What type of offer would be best for customers?

- What should be the shipping strategy?

- How should suppliers perform?

- To what extent can you scale up a business?

4. Cognitive Analytics

Cognitive analytics help organizations answer complex questions in human language. Technologies like AI, machine learning, and natural language processing help companies learn about specific business functions to get insights about customers, competitors, market perceptions, and the likewise.

5. Machine Learning

The future of the supply chain seems to be bright for those organizations who are keen to integrate modern-age technologies like AI and machine learning in their operations. To understand the importance of data analytics in supply chain management think of your warehouses being operated by machines that you can control at your fingertips. These machines are always in self-learning mode ensuring productivity without hampering time and cost. Machine learning uses algorithms to automatically identify patterns in data and make predictions and recommendations in the warehouse.

Benefits of Supply Chain Data Analytics For SCM Managers

*quantzig.com

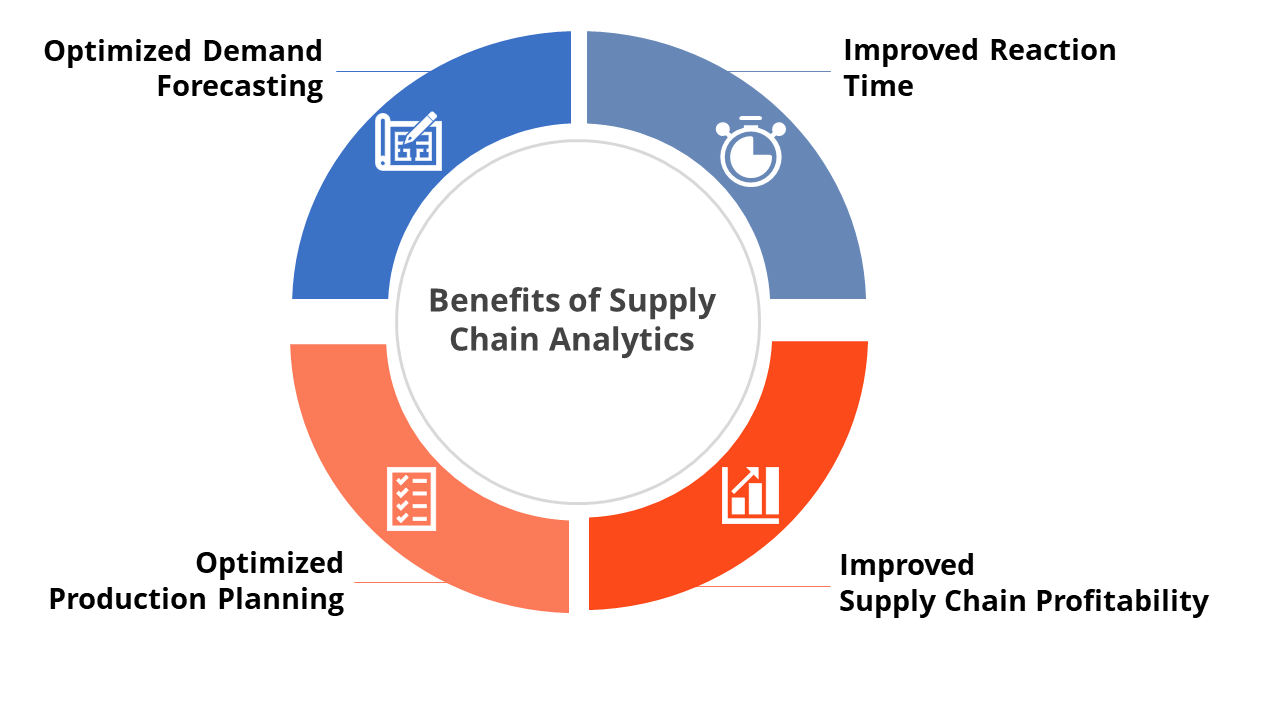

Now that we know the use-case of data analytics in supply chain management, let’s figure out the importance of supply chain data analytics. From a layman’s point of view, as companies grow and go digital, they need to inculcate the habit of grabbing, reading, and using data to dig out insights that help organizations make strategic decisions on enhancing their supply chain capabilities. Here are 7 benefits of supply chain data analytics –

For Forecasting & Demand Planning

Supply chain data analytics help organizations analyze their past data to make more accurate predictions about what the future is going to look like. This helps companies optimize their production schedules and reduce the risk of stockouts or overstocking.

Enhance Inventory Management

Supply chain data analytics help organizations better understand their inventory levels, and turnover rates, which can help them optimize their stocking and replenishment processes.

Better Supplier Management

By analyzing data on supplier performance, companies can identify and address issues that may be impacting their supply chain.

Visibility & Traceability

Supply chain data analytics can be used to track products as they move through the supply chain, providing companies with greater visibility into the location and status of their goods.

Cost Reduction

The importance of data analytics in the supply chain is that it helps companies reduce costs to a great extent. By leveraging data analytics, companies can reduce costs related to inventory, transportation, logistics, and many other supply-chain expenses.

Improved Customer Service

By using supply chain data analytics to gain insights into customer demand, companies can improve their ability to meet the needs of their customers and increase satisfaction.

Managing Risks

Supply chain analytics can help organizations identify and mitigate various business risks like supply disruption, logistics issues, or any other risk that can hamper the free flow of goods from warehouses to consumers.

Kickstart Your Career in Supply Chain Data Analytics with Jaro Education

Jaro Education, as a marketing and technology partner, presents the Post Graduate Certificate Programme in Supply Chain Operations & Analytics (SCOA) by IIM Nagpur which gives you an excellent opportunity to acquire skills and expertise needed in supply chain data analytics management. Be it a fresher or a working professional, this world-class programme is suitable for both and enhances your acumen in the manufacturing, services, and logistics sectors. More details about this programme are given below –

| Duration | 12 months |

|---|---|

| Eligibility | -Bachelor’s Degree (any specialization) or Diploma (10+2+3 acceptable) with a minimum of 50% marks. -Minimum of 2 years of work experience is required. |

| Syllabus Run-Through | Fundamentals of Operations Management & Process Analysis, Supply Chain Management & Strategies, Inventory Management, Quality Management & Process Control, Quantitative Techniques for OM/SCM, Supply Chain Design & Management, Analytics in Operations & Supply Chain and Management Sciences, Lean Operations Management & Six Sigma, Project Management, Service Operations Management, and much more. |

| Programme Fee | Application Fee: ₹2360 Total Fee (excluding application fee): ₹2,50,000 (Application fee is inclusive of 18% GST) |

With Jaro Education, you can excel your career as a supply chain manager and seize the opportunity to integrate data into the operations. Here’s how Jaro Education plays a pivotal role in your career growth and development –

- You get constant learning support.

- Unparalleled career guidance and support.

- Dedicated support for students throughout.

- Lifelong learning experience.

- Leverage peer-to-peer learning.

- Get full access to discussions and forums for enhanced learning.

- Stay up-to-date with the latest insights from Alma Meter.

- Access to alumni events and other benefits.

- Get full access to Jaro’s alumni network of 3,50,000 professionals.

Frequently Asked Questions

Cybercriminals are continuously improving their attacking abilities with the help of AI. Now they are launching large-scale attacks by integrating AI technologies into their workflows. To prevent these attacks, you should utilise AI to analyse large volumes of data, reducing false positives from security alerts and cutting out bottlenecks from security alerts.

To become a professional in supply chain data analytics, you can pursue a 12month-long Post Graduate Certificate Programme in Supply Chain Operations & Analytics (SCOA) by IIM Nagpur. Post-completion, you will be eligible to sit for interviews.

It is not difficult if you love extracting and reading data and converting the data into meaningful insights. Supply chain data analytics is the field of management where your management knowledge and your passion for turning data into insights will be put on a litmus test.

As a supply chain data analyst you will play an important role in planning, analyzing, and monitoring a company’s supply chain distribution to ensure products make it to their destination in a time and cost-efficient manner by leveraging data and strategic decision-making.