How To Optimize Economic Order Quantity (EOQ) For More Profits?

Table of Contents

- jaro education

- 14, August 2024

- 2:00 pm

Introduction

Effective inventory management is very essential to a business interested in cutting down on costs and making immense profits. To strike a balance, a business should work towards maintaining its economic order quantity. But what is economic order quantity, and how do you calculate it? Is the formula for EOQ applicable in practice? Let’s discuss all these in detail.

Be it a professional with decades of experience in supply chain management or a tyro in the field—the secret to inventory management lies in mastering economic order quantity for heightened success and keeping pace with the new, developing trends. Such training programs will help you leverage economic order quantity and other analytic tools with the requisite knowledge and skills to ensure your business stays afloat amidst the competition.

*CashflowInventory

What is Economic Order Quantity?

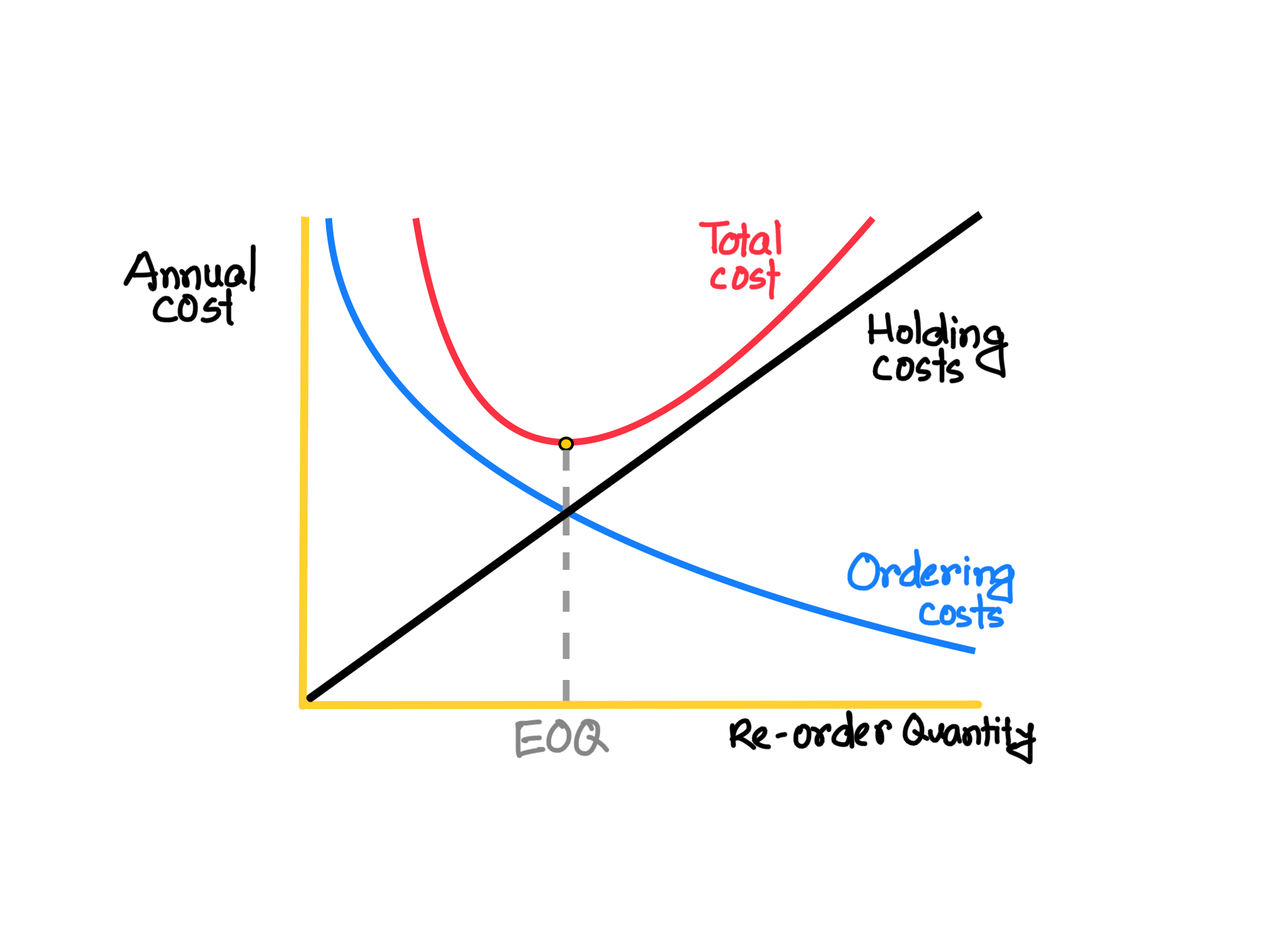

EOQ is an inventory management formula that determines the right balancing quantity at which the order and inventory holding costs are at a minimum. The costs associated with this formula are:

- The costs of ordering: costs that are incurred every time an order is made, which may include administrative costs, shipping costs, and handling costs

- The costs of holding: costs incurred in storing inventory, including warehousing costs, insurance, and depreciation.

- Stockout Costs: These are the costs resulting from stockouts. Lost sales and irate customers all belong to one big classification of stockout costs.

Economic order quantity allows firms to find the best balance or trade-off between these two kinds of costs. Thus it ensures that a firm maintains efficient levels of inventory without over and under-stocking.

The EOQ Formula

The EOQ formula arises from a model that assumes the following:

- Constant demand rate

- Constant lead time

- Fixed cost of placing an order

- Fixed cost of holding inventory

- No stock-outs are allowed.

EOQ Equation :

EOQ= √ 2DS ∕H

D = Demand rate (units per period)

S = Ordering cost per order

H = Holding cost per unit per period

Let us understand each component one by one and its meaning.

Demand Rate (D)

The demand rate would be the number of units that will be required over a given period. This may be in terms of a year, month, or any other period that is feasible for the operation of the business. Coming up with an appropriate forecast of demand is very important in economic order quantity estimation, as it is a major part determining of inventory decisions.

Ordering Cost (S)

Ordering costs are the expenses incurred, such as necessary paperwork, in making an order. Shipment and handling are part of the ordering costs. The lowest ordering costs will enable more orders to be made, but high ordering costs may compel you to make fewer, bigger orders.

Holding Cost (H)

Holding costs represent all those expenses involved in storing unsold inventory. Generally, these include warehousing, insurance, and depreciation. High holding costs motivate companies to maintain smaller inventories while low holding costs would allow larger inventories.

How to Calculate EOQ: Step-by-Step

Let us work through an example to understand how the economic order quantity formula works in real life.

Let us assume we have a firm, ABC Corp., with the following information:

- Annual demand, D = 10,000 units

- Ordering cost per order, S = $50

- Holding cost per unit per year (H): $2

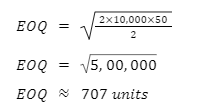

Using the EOQ formula:

This means that ABC Corp should order approximately 707 units each time they place an order to minimize their total inventory costs.

Benefits of Using Economic Order Quantity

- Cost Reduction: EOQ helps significantly reduce total inventory costs by balancing ordering and holding expenses.

- Efficient Inventory Management: EOQ verifies that the inventory level is such that all risks like overstocking and stock-outs are at a minimum.

- Improved Cash Flow: By minimizing the extra stock, the money involved in unsold inventory is released and made available for use in some other part of the business.

- Smoothing Operations: EOQ helps in better planning and therefore smoothens operational processes, which increases efficiency.

Assumptions and Limitations of EOQ

As powerful and useful as it is, some assumptions and limitations of this model exist:

- Constant Demand: It assumes demand over a period is constant and perfectly predictable, which in most cases is not true.

- Instantaneous Replenishment: It assumes that inventory is replenished instantaneously without considering lead time.

- Fixed Costs: It is dependent on fixed ordering, holding, and carrying costs, which vary with time.

Modifying EOQ for Practical Applications

The Economic order quantity can be made more dynamic in application to business dynamism by incorporating lead time, demand, and cost as elements of variables in the following ways:

- Safety Stock: Add safety stock to account for variations in demand and the uncertainty in arriving on time.

- Periodic Review: Regular review of the economic order quantity calculus when changes in demand and cost structures have taken place.

- Supplier Collaboration: Coordinating with suppliers to minimize the lead time and the cost of placing the order.

More EOQ Models around

The simple economic order quantity formula is only one among several other extended models built for various special applications. Some of them are given below:

- Quantity Discount Model: Account for the price breaks available at different order quantities. Find the order quantity at which the total cost is minimum, taking into consideration the lowest purchase price as well as ordering/holding costs.

- Production Order Quantity Model: Used when the inventory is produced in-house rather than bought, taking into consideration the rate of production and set-up cost.

- Multi-item EOQ Model: It corresponds to the cases where several products are managed jointly, setting the total cost of all items jointly at the minimum level.

EOQ in Modern Business Analytics

Finally, advanced analytics and Business Intelligence tools bring the possibility of further refinement of economic order quantity calculation with real-time data infusion and predictive analytics. With the Professional Certificate Programme in Advanced Analytics and Business Intelligence by IIM Kozhikode, one can take up important skills of such a kind of tools, integrating which can make inventory management decisions quite realistic and dynamic.

EOQ and Supply Chain Optimization

The integration of economic order quantity into other supply chain management practices will result in substantial improvements in overall efficiency. Following is how EOQ helps in the optimization of supply chains.

Demand Forecasting

EOQ is related to demand forecasting. With the availability of several historical sales data and advanced analytics, it is now possible to accurately forecast future demand and hence arrive at better EOQ calculations, which in turn reduce stockouts.

Just-in-Time (JIT) Inventory

EOQ complements the Just-in-Time (JIT) inventory approach very well. JIT is an inventory system that intends to reduce inventory levels by receiving goods in time to be used in the production process. Economic Order Quantity will give the optimum order quantity so that the inventory arrives just in time to meet demand without extra holding costs.

VMI - Vendor-Managed Inventory

In a VMI system, the supplier manages the inventory level for the customer. Consequently, by sharing EOQ computations with all suppliers, the system will optimize order quantities and thus increase the efficiency of VMI systems in any business.

An increase in inventory turnover rate

EOQ allows high turnover rates by decreasing the amount of and hence reducing excess inventory held. An increased inventory turnover rate means that more efficient management of inventory and hence better use of resources are taking place.

Implementation of EOQ in your business

Economic order quantity implementation in your business necessitates several steps that need to be implemented in such a way that it blends well with the operational objectives and supply chain strategies. There are the steps:

- Data Collection: Collect data on the rate of demand, costs of ordering, and holding costs. This data will form the basis of your calculations of EOQ.

- EOQ Calculation: The EOQ formula helps in finding the optimum order quantity and should be refreshed regularly to accommodate the changes in demand and costs.

- Integrating inventory system: Leverage the EOQ-based logic in current inventory management systems that can then drive order placements in an automated manner, thus applying economic order quantity consistently.

- Collaboration with suppliers: Because of the economic order quantity, work out order quantities with your suppliers. Generally, this may help guarantee better lead times, reduce ordering costs, and ensure efficiency.

- Continuous Improvement: EOQ should be checked and rectified at regular intervals. The inputs of supply chain operations should be used to fine-tune these parameters, hence, achieving an optimum level of inventory.

Deeper Look: The Future of Inventory Management

Currently, management systems are being influenced by technological innovation and increasing access to real-time data. Certainly, economic order quantity will be one of the integral parts, but its application will be modified through new tools and methodologies. The following trends will develop the discussed area.

Artificial Intelligence and Machine Learning

These algorithms can optimize economic order quantity calculations through the processing of big reams of data to arrive at better predictions of demand. AI and machine learning algorithms can spot patterns and trends that traditional methods may not be able to pinpoint.

IoT and Real-Time Tracking

Internet of Things (IoT) for the real-time tracking of inventory levels and thus holding relevant information concerning stock status for any business. If IoT is integrated with economic order quantity calculations, this leads to responsive and adaptive inventory management.

Blockchain for Supply Chain Transparency

Blockchain technology can be used to enhance supply chain transparency and traceability. Giving an immutable and secure transaction record, the blockchain can therefore lead to trust and collaboration between the parties in the supply chain to optimize economic order quantity calculation and reduce inefficiencies.

Green Inventory and Sustainability

With sustainability topping the priority list of businesses, EOQ calculations can also be adjusted to take into account environmental factors in a model of economic order quantity that incorporates sustainable inventory practices based on reducing wastage and optimizing the usage of resources.

Conclusion

Economic Order Quantity is still regarded as one of the most basic tools that guide enterprises toward this perfect balance in their inventory management processes. The study of the economic order quantity formula and supply chain analysis around it opened the doors for massive savings and operational efficiencies for companies. The move of EOQ with modern analytical aids and data-driven methodologies will only make economic order quantity more effective with technological advancement. This will be the path to more intelligent and sustainable inventory management.

![Best-IIM-Online-Courses-with-Certification-[2025]](https://jaro-website.s3.ap-south-1.amazonaws.com/2025/04/Best-IIM-Online-Courses-with-Certification-2025-1024x576.webp)