The Role of Production Managers: Skills and Responsibilities

Table of Contents

- jaro education

- 2, February 2024

- 11:00 am

Production Managers are specialists who coordinate the entire production process and make sure adequate resources are available. They are responsible for creating budgets, allocating project expenditures, and scheduling the human resources necessary to guarantee that work gets completed by the projected deadline. It mandates hard-core professionalism and job specialization.

What Skills Do Production Managers Require?

The role of Production Managers lies in the ability to carry out the ideal manufacturing process. These comprise technical abilities specific to a given product or industry and soft skills that support an effective production process. A production manager can acquire these skills via educational programs, on-the-job training, and practical work experience. These experts can apply their production management skills to a variety of industries, such as electronics, food manufacturing, pharmaceutical development, aerospace design, and defence development.

*edurka.co

The following are the critical skill sets that will enable one to achieve cardinal success as a production manager:

Leadership

With the ability to motivate team members to meet production targets and acquire new skills, a production manager can seamlessly and effectively lead the team.

Management

This competence encompasses all of the tasks necessary to lead a production department properly. To meet production targets, the production manager might, for instance, include training modules for employees of related departments, maintain morale among workers, arrange staff schedules, and cascade the doctrines of the division of labour down the line.

Teamwork

This skill involves working well with a production team to achieve common objectives. A production manager could lead team-building exercises to assist employees in developing fruitful work interactions and environments.

Verbal Communication

A proficient production manager can frequently interact with coworkers, suppliers, and upper management.

Written Communication

Using reports, emails, notes, presentations, and text messages, the floor manager may efficiently exchange information and work together with the production team.

Empathy

By comprehending a coworker’s or client’s feelings or responses in a particular circumstance, a production manager may frequently relate to them and settle disputes and discrepancies.

Equipment Maintenance

This skill comprises inspecting, changing, or fixing any equipment needed for a manufacturing process. It may also involve alerting the top hierarchy to unsafe practices and problems with machinery or eliminating machine-related waste.

Patience

During manufacturing, production managers can typically restrain their impulses and wait for the ideal moment to communicate with supervisors, team members, and subordinates.

Project Management

By assigning responsibilities wisely, a seasoned and experienced production manager usually oversees every step of the production process. It involves utilizing a project management technique, monitoring quality control, organizing and enhancing workflow and project flow, discussing and determining project budgets and deadlines with clients and stakeholders, and uplifting industrial process standards and efficiency.

Conscientiousness

Skilled managers are capable of managing jobs systematically and with care, allowing them to find and resolve industrial process flaws with ease.

Time Management

Production managers are adept at planning a workday, hitting deadlines, and supervising the efficient operation of industrial processes.

Problem-Solving

The project manager can anticipate problems and come up with practical solutions, which is crucial for tracking the progress of a company toward its goal.

Collaboration

One of the most essential capabilities for production managers is typically working in tandem with the production wing, departments of finance, and human resources (HR) to figure out the resources required for production processes and to allocate corporate funds logically.

Knowledge of Software Applications

This expertise enables a manager to convey the status and results of the production project using word processing and organizing applications like Word, Excel, and PowerPoint.

Email Management

Since production managers frequently communicate via email with a host of stakeholders and coworkers during the day to address concerns and troubleshoot production, handling email correspondence is a critical ability for these professionals.

Multitasking

To guarantee that every operation delivers high-quality outcomes, the concerned manager should possess the ability to handle multiple manufacturing actions at the same time.

Financial Expertise

Production Managers who possess this skill are capable of funding projects with greater efficiency. It involves assessing the resources required, projecting costs, identifying methods to cut costs, and working with clients and the senior management layer to create a budget.

Industry Knowledge

It refers to the fundamental abilities unique to a given sector, such as food processing or aircraft manufacturing. Critical competencies for a food production manager include, for instance, keeping stock levels up to date and ensuring that raw food ingredients are stored properly to prevent waste.

Understanding of EPA Regulations

This cognition calls for familiarity with EPA regulations. Production Managers frequently enforce compliance with federal environmental protection regulations within the shop floor.

OSHA Standards

One of the most profound production manager skills is adhering to OSHA’s health and safety regulations. It relates to staying current with statutes, organizing initiatives to prevent accidents, advocating for safety procedures, informing upper management of non-compliance, and communicating with supervisors.

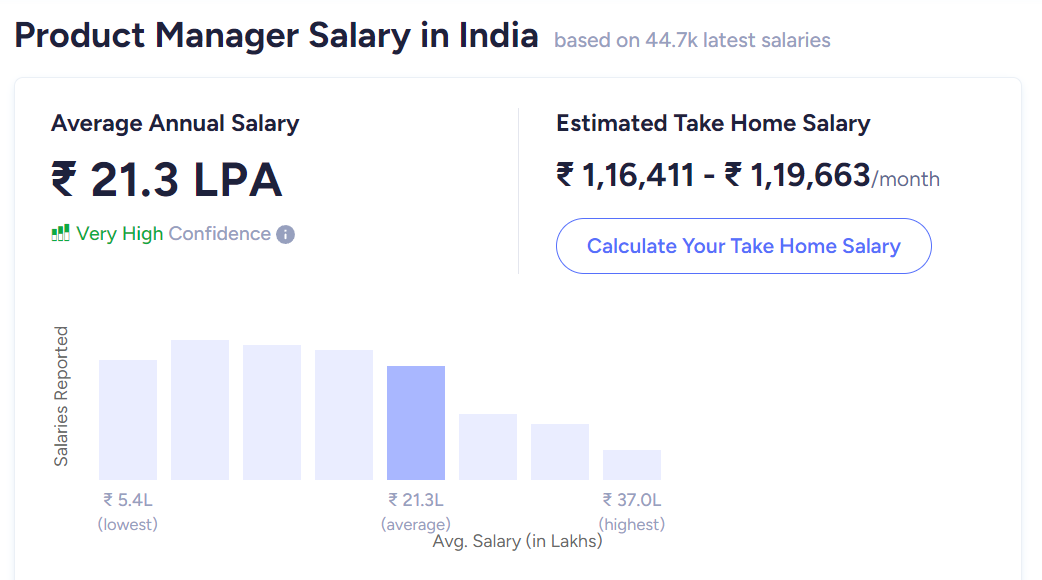

*ambitionbox.com

What are the Critical Responsibilities of a Production Manager?

A production manager oversees the planning, coordinating, and controlling a company’s manufacturing process. The product manager handles everything from production and quality control to on-time product delivery. The eight primary responsibilities ascribed to product managers are mentioned below:

1. Planning and Organizing the Process of Production

The primary responsibility of a production manager is planning the production process of the product. The most crucial variable in any industrial organization’s success is the product it delivers. The corporate entity must choose what it will offer to the market, how it will be created, and when it will be produced based on its vision, mission, and objectives.This production planning process must get started and overseen by the production manager. The strategy should be viable to handle competition in the intended market and be in line with the company’s production goals and sales projections.

2. Management and Control of the Production Cycle

An efficient system that can manage the complete production process is essential for achieving excellent production planning. A production control system is mandatory to carry out the production plan properly. The production process must be finished successfully, on schedule, and for the most minor investment. Appropriate production control must be implemented to get things done optimally. In addition, by raising productivity, a production control system guarantees uninterrupted production.

Thus, implementing a production control system that is best suited for production planning rooted in the product’s nature is an essential responsibility of the production manager.

3. Monitoring Quality Control

The manager responsible for the production process is exceptionally concerned about quality and product planning. Ensuring the product maintains the requisite quality throughout the production process is vital. Keeping an eye on a product’s unfavourable aspects that could affect the final product’s quality is the goal of quality control.

The managers should thus take all necessary steps to ensure that the quality standards are upheld throughout the production process because, in a competitive market, the quality of the product can have a significant impact. Controlling the production process’s optimum quality can be facilitated using a comprehensive and foolproof quality management system.

There are multiple options available for manufacturing processes. While some approaches are more cost-effective, others offer superior advantages. Every option has benefits and drawbacks of its own.

To determine the best and most rewarding manufacturing techniques for the product that will guarantee a high-quality spin-off, an efficient production manager must first identify all accessible production procedures and weigh their pros and cons. The analysis aspect determines which approach, out of all the available options, is the most suitable. The best strategy should be able to raise process productivity while lowering manufacturing costs.

4. Inventory control

Another vital responsibility of a production manager is to exercise proper control over the inventory. He is responsible for analyzing the production process and determining the economic order level, minimum, maximum, and average material rankings with a proper understanding of the production process and inventory consumption to avoid overstocking or understocking inventories.

5. Plant Arrangement and Layout

Product managers have an integral role in building and maintaining a production plant. They ensure that the production plant is built with safety and is suitably constructed inside and outside to facilitate the implementation of simple production processes. Besides, they also confirm that no production activity pollutes the factory’s surrounding environment, all of the requirements are considered while designing the plant’s layout, and the available resources are arranged inside the structure to maximize process productivity criteria and optimal utilization while keeping running costs to a bare minimum.

6. Work Measurement Techniques

It is crucial for product managers to implement work-measuring techniques to gauge how well the operational workforce is doing in the manufacturing process. Work-measuring tactics can be applied through time and motion investigations. When an employee performs below the benchmark set by work measuring methodologies, it becomes essential to determine the root cause of the underperformance and implement the appropriate corrective measures to boost morale and maximize output.

7. Motivation in the Process

By offering monetary incentives, production managers should be able to stimulate employees’ enthusiasm to put more effort into the manufacturing process. As factory workers’ productivity rises with continual appreciation, it is vital to any industrial setup.

Conclusion

To sum up, team leadership and inducing inspiration are vital competencies for a production manager to achieve operational excellence. Effective team management also involves developing talent, encouraging collaboration, and creating a healthy work environment on the factory premises.

To thrive as a product manager, professionals can choose to be a part of the Advanced Strategy For Products And Marketing – Advanced Analytics For Products And Marketing, a dual certification course offered by IIM Kozhikode, as it provides you with the opportunity to interact be with IIM’s core faculty and be part of live interactive lectures, which, in turn, will help you gain expertise in new-age concepts like Cluster Analysis, Logistics Regression, Perceptual Dimensions, etc. To know more, reach out to Jaro Education and learn about the admission procedure.