How To Select The Right Forecasting Technique?

Now, in such a wide sea of methods and techniques, how can you tell which one is the right way? This blog delves into the details of various types of forecasts and the alternatives in methods, comprehensively helping manufacturing managers make a choice.

For those who want to go a little deeper into the forecasting side and want to know a bit more on the manufacturing management front, you get a thorough understanding of the Post Graduate Certificate Programme in Manufacturing Management & Analytics provided by the IIM Tiruchirappalli.

Table Of Content

A Comprehensive Guide to Forecasting Techniques

Choosing the Right Forecasting Technique

What Is Sale Forecasting?

What Are The Types Of Sales Forecasting Methods?

How Do You Select An Appropriate Sales Forecasting Technique?

Practical Application in Manufacturing Management

What Is Business Forecasting?

What Are The Types Of Business Forecasting Methods?

Impact of Forecasting Methods on Business Growth

How To Learn Forecasting Techniques In Depth?

Explore Career Opportunities Under Jaro Education Guidance?

Conclusion

Frequently Asked Questions

A Comprehensive Guide to Forecasting Techniques

Choosing the Right Forecasting Technique

What Is Sale Forecasting?

Forecasting sales is an art that helps the organisation estimate the total revenue or count of deals that it will be able to close in the future based on prior data.

organisation

Sales organisations integrate private historical data, applicable public economic metrics, and historical patterns to get a glimpse of broader or narrower forecasts of a company’s possibilities. Forecasts serve as benchmarks for months, quarters, or years, and they may also serve as components in team commission calculations.

Forecasting can be understood as one of the most fundamental top-tier areas in business analytics. This is because the sales forecast forms the basis for developing strategies for building new business associates, sending to targeted accounts, and estimating replenishment needs for shopfronts in the geographic context.

Facts form the basis of sales forecasting, but uncertainty and risk also contribute to the overall figure. This is because uncertainty is, well, uncertain, and the imagined effects of risk-taking are not wholly predictable as well; it is better to always bear in mind that a forecast may not come true a hundred per cent. But it is always better to have an umbrella handy and leave it unused than be caught in a sudden downpour without it.

What Are The Types Of Sales Forecasting Methods?

Data alone is the raw material referred to; one may just face sales depending on the techniques applied in forecasting. Different forecasting techniques can be used according to what information is being valued from the given sales figures; one could use internal or external factors for businesses. However, those expressions can mainly be entered into two general forecasts, which are:

- Qualitative sales forecasting: The intangible qualities that turn into potential sales and income are predicted through the opinion, judgement, and insight of an expert.

- Quantitative sales forecasting: This method, while forecasting future revenue, depends heavily on the performance figures and historical developments of sales and income.

How Do You Select An Appropriate Sales Forecasting Technique?

All sales forecasting methodologies outlined above are for answering the question: “What performance can one expect from sales in a given period?”

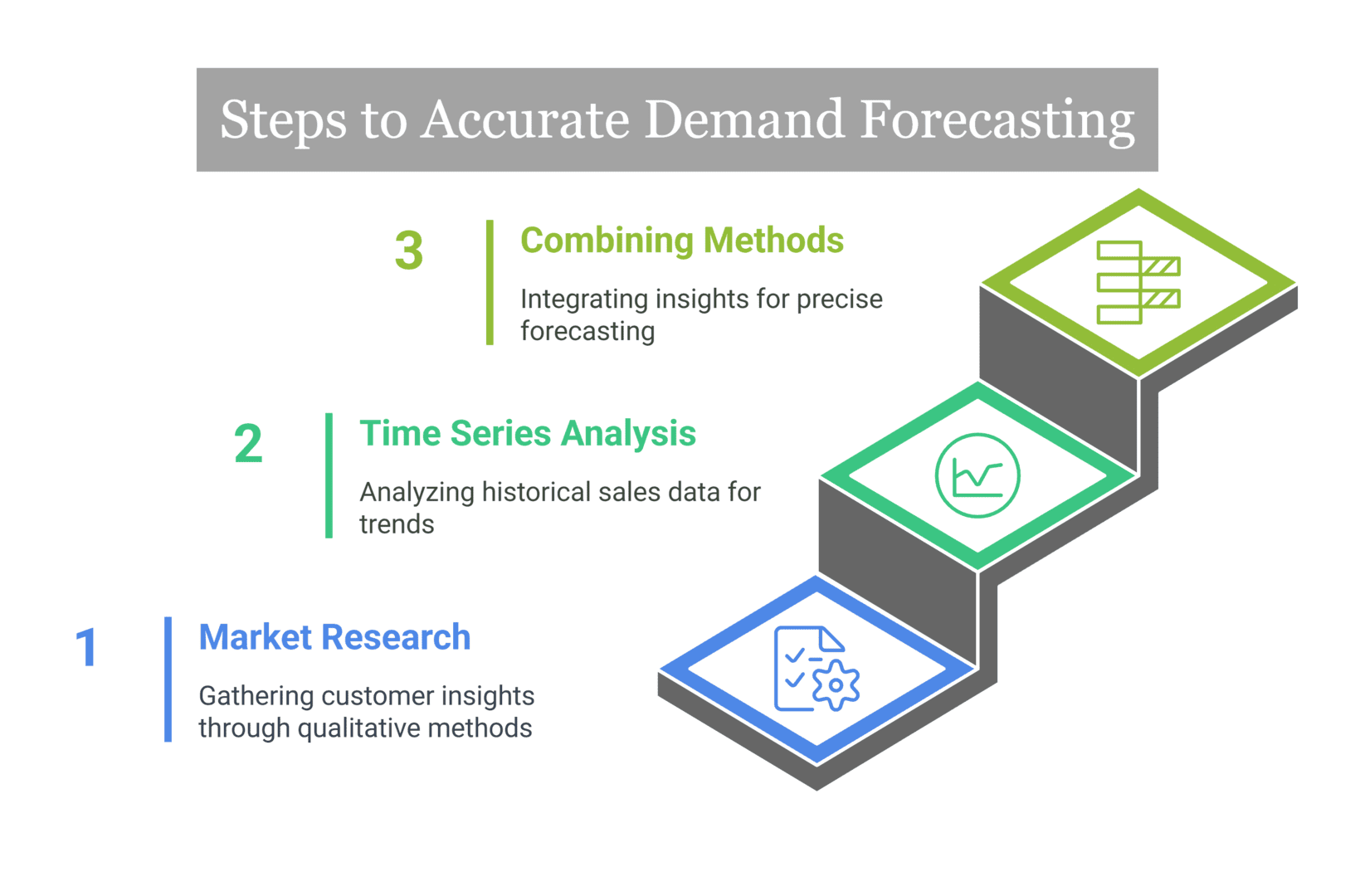

Regardless of the model you select, follow these steps to use it effectively:

Step 1: Define Your Plan

Clearly state the problem and what the forecast information will be used for, identify for whom the findings will be intended, and decide how responsibilities will be allocated for carrying out the forecasting project.

Step 2: Gather materials

It should contain relevant data, information from your CRM, and tools you may need to complete your chosen sales forecasting model.

Step 3: Conduct a preliminary analysis

What will be your expected results for this forecast? Consider some relevant things like seasonality, as you will compare your expectations later with the result. Consider also the pros and cons of that particular sales forecast method you are using and how this may influence your view about its prediction.

Step 4: Use your sales forecasting model

Run your model and look for an output. The output must follow logically from the question you asked. If not, debug it and run it again. Be sure to document results from each run as redundancy precautions.

Step 5: Time to evaluate the outcome

Did the information produced through the sales forecasting method make sense in your expectations or the lack thereof? In case this output data came to fruition, how would it affect the activities of your sales team moving forward?

Practical Application in Manufacturing Management

What Is Business Forecasting?

What Are The Types Of Business Forecasting Methods?

Impact of Forecasting Methods on Business Growth

| Advanced Forecasting Techniques | Organisations that require more complex forecasting techniques have various advanced solutions at their disposal, including machine learning and artificial intelligence. |

| Machine Learning | Machine learning algorithms can analyse, identify, and predict highly complex patterns based on large data sets using regression analysis, neural networks, and decision tree techniques. Some common forecasting methods in machine learning include regression analysis, neural networks, and decision tree techniques. |

| Artificial Intelligence | AI-powered forecasting systems can continuously learn and adapt to new data, improving their accuracy over time. These systems can handle complex scenarios, such as predicting the impact of external factors like economic shifts or competitor actions on demand. |

How To Learn Forecasting Techniques In Depth?

About IIM Trichy

IIM Tiruchirappalli (IIMT) is one of the fastest-growing generational IIMs and now houses state-of-the-art campus facilities covering 174 acres. Since its establishment in 2011, the Institute has successfully established itself as a top-tier management institution, renowned for its ability to generate and share management knowledge. The Higher Education Forum (HEF) awarded IIM Tiruchirappalli with the Leadership & Innovation Award: 2020 in the Business School Category at the 11th HEF Annual Convention. In the Outlook-ICARE India MBA Rankings 2020, the institute ranked seventh among such top B-schools. The National Institutional Ranking Framework, Ministry of Human Resource Development, Government of India (2023), awarded IIM Tiruchirappalli a rank of 22 among management institutions. The e-Learning Centre of Executive Education and Consultancy (EEC) extends further into the mission of IIMT by reaching out to aspiring executives, keeping in mind their limitations of time and space. Thus, the e-learning programmes enable IIMT to enter the online executive education space, focusing on delivering quality management education that is both contemporary and affordable.

Programme Overview:

Typically, manufacturing is considered a complex system because of the interacting processes. The activities and resources of these processes generate data in huge volumes that are hardly captured or effectively utilised. With the development and emphasis on analytics, it has become imperative to derive insights from this data for informed decision-making at a micro and macro level. Executives in manufacturing industries must quickly adapt and respond to these challenges in a tailored manner.

Befriend the upcoming growth path through the Post Graduate Certificate Programme in Manufacturing Management and Analytics offered by IIM Tiruchirappalli. This interdisciplinary programme is geared towards equipping professionals with fundamental concepts, techniques, and tools for managing manufacturing systems with analytics in a very practical way. The program will also help participants deal with quantitative reasoning and gain insights to strengthen their planning, increase production efficiencies and yield, and enhance performance into the future, thus benefiting the bottom line, thanks to hands-on exercises, practical applications, and case studies.

In addition, the schedule for the program is written and arranged such that the weekend classes are fitting for the poor timing of working professionals.

Admission Requirements

Eligibility requirements include:

- A Bachelor’s Degree with a minimum of 50% marks or CGPA equivalent (45% for SC/ST/PWD candidates) from a recognized university;

- An equivalent qualification recognized by the Ministry of HRD, Government of India;

- The candidate must have a minimum of 1 year of post-qualification experience.

- Reservations will be available to eligible candidates in accordance with Government of India norms.

Explore Career Opportunities Under Jaro Education Guidance?

Conclusion

Frequently Asked Questions

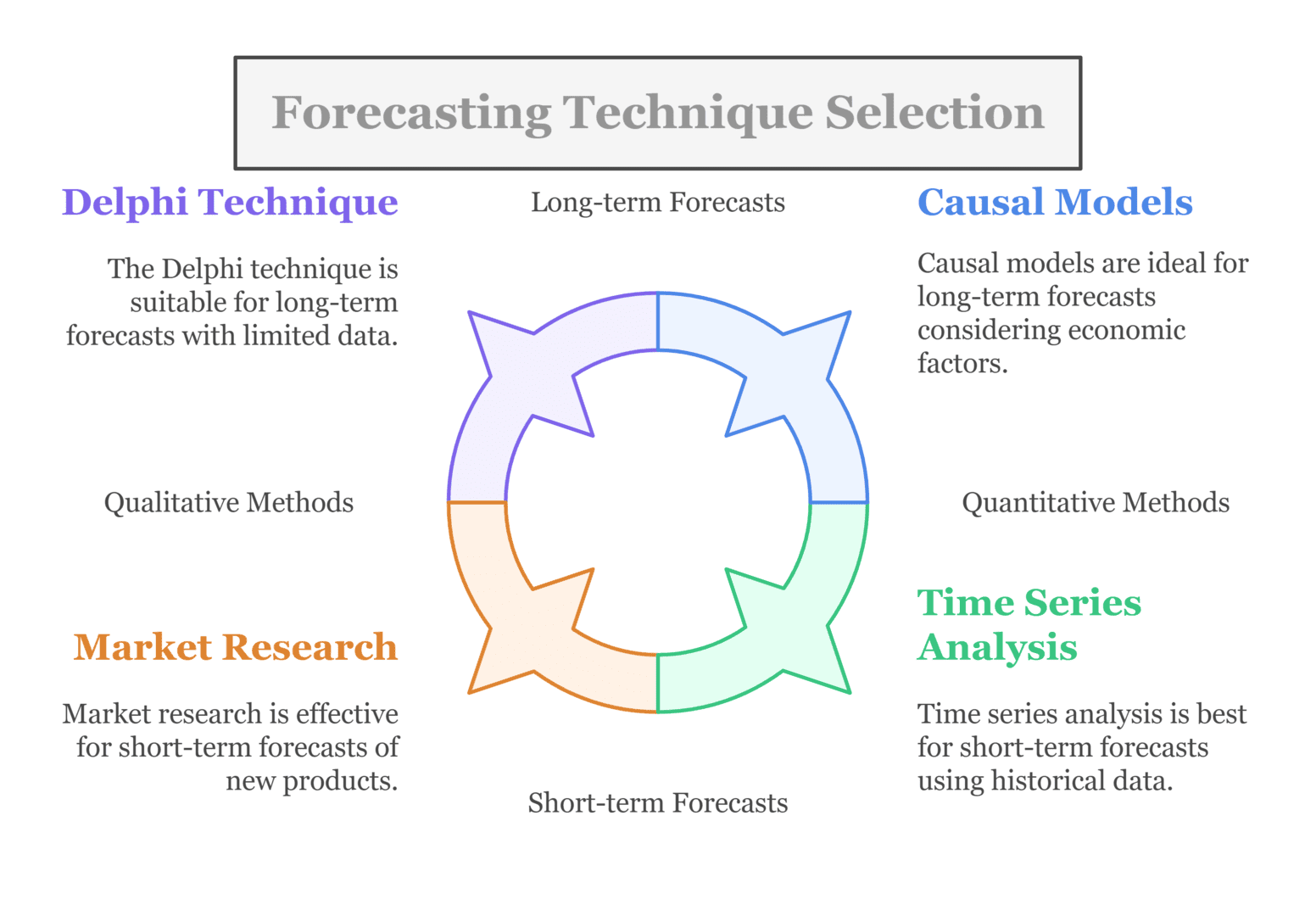

The most common sales forecasting methods include:

- Qualitative Methods: These rely on subjective judgements, market research, and expert opinions, often used when there’s limited historical data or for new products.

- Sales Force Composite: Involves input from salespeople to estimate future sales.

- Delphi Method: A group of experts independently forecasts sales, and their feedback is consolidated to create a final estimate.

- Market Research: Collect data from potential customers to predict future sales.

- Quantitative Methods: These use historical data and mathematical models to predict future sales.

- Time Series Analysis: Uses historical sales data to predict future trends, often involving moving averages or exponential smoothing.

- Causal Models: Relies on identifying relationships between sales and external factors (e.g., advertising spend, market conditions) to predict future sales.

- Qualitative forecasting relies on subjective data and expert opinion and is often used when there is little to no historical data or for new products and services.

- Quantitative forecasting uses historical data and statistical methods to predict future sales, making it more objective and reliable, especially for established products.

- If the product is new or in a rapidly changing market, qualitative methods like sales force composite or market research may be more effective.

- For established products with sufficient historical data, quantitative methods such as time series analysis or causal models are more appropriate.