The Outstanding Power of Manufacturing Analytics

Table of Contents

In developing nations, the manufacturing sector continues to be one of the most important aspects of economic growth, providing a lot of job opportunities and making a substantial contribution to a nation’s GDP, particularly in a developing country like India.

Manufacturing is the secondary sector of the Indian economy. Manufacturing is the process of turning raw material into finished goods using labour, machinery, capital, etc.

Analytics is a process in which we examine & interpret a large amount of data to find certain patterns and make predictions.

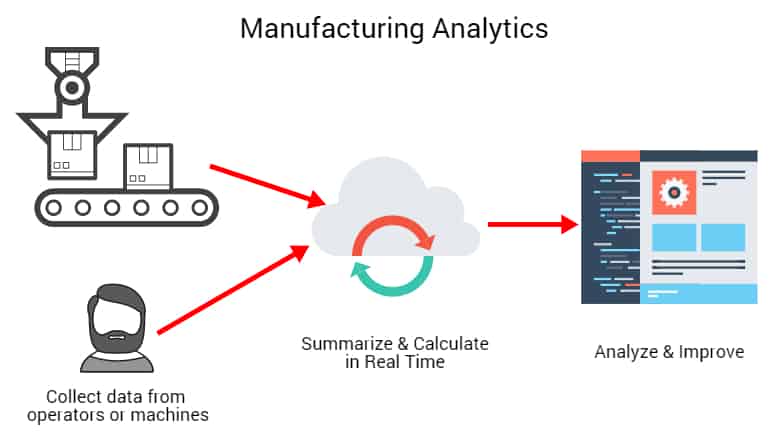

Manufacturing analytics is a process that involves taking data from the manufacturing process and analyzing it to improve efficiency, optimize processes, and make informed decisions.

Professionals are now able to solve complex problems of production processes, thanks to the advancement of manufacturing analytics. Industries are increasing their productivity, cutting expenses, and coming up with innovative ideas by implementing data analytics in manufacturing.

This blog examines how supply chain and manufacturing analytics are revolutionizing the manufacturing sector and how professionals can advance their careers by mastering these techniques.

What is Manufacturing Analytics?

Manufacturing analytics is nothing but interpreting manufacturing data and applying data-driven insights to optimize the processes, boost productivity, and improve overall performance in the manufacturing sector. Businesses can make more profit at lower costs thanks to manufacturing analytics. It gives people the ability to bridge the gap between raw, scattered data and strategies that actually work.

Manufacturing analytics is becoming extremely important as the world moves forward. It combines cutting-edge technologies like supply chain analytics, machine learning, and artificial intelligence (AI) to solve problems and open doors for expansion & innovation.

*mingosmartfactory.com

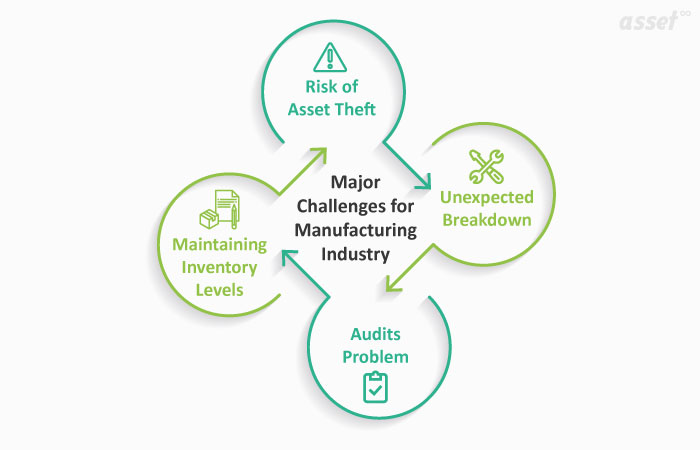

Challenges in the Manufacturing Industry

Lack of Skills

India’s manufacturing sector continues to struggle with a lack of skilled labour force. A study by National Skill Development Corporation (NSDC) found that the demand for skilled workers stands at 103 million, while the supply is only 74 million, highlighting a critical gap. This imbalance shows the urgent need for focused skilled initiatives, especially in high-demand roles like automation engineers & quality assurance assistants.

*indiatoday

Operational Costs

For many businesses, cutting operational expenses is a top priority, and intelligent supply chain analytics provides a workable answer. Finding inefficiencies like bottlenecks, needless costs, or underutilized resources is made simpler by utilizing advanced data insights. These tools offer practical suggestions for streamlining workflows, optimizing procedures, and making sure resources are distributed efficiently. In addition to lowering costs right away, this strategy improves supply chain agility generally, allowing companies to anticipate market demands and reduce risks. Integrating such analytics is not only a strategy but also a necessity in the current competitive landscape.

Lack of Resources

Lack of resources is a problem for many companies, which is made worse by under-trained employees. Delays and decreased productivity frequently result from this, which has an impact on the entire company. Teams feel overburdened and unprepared, which causes tasks to accumulate, deadlines to be pushed, and general morale to decline. It simply doesn’t function well, like attempting to construct a house without half of the necessary tools. Not only is it a nice-to-have, but investing in appropriate training and resource optimization is the cornerstone of sustaining seamless operations and inspiring teams to deliver their best work.

Issues in Quality and Planning

Inadequate planning and poor quality management continue to be major problems for businesses, frequently leading to missed opportunities and resource waste. Moreover, another major obstacle is efficient inventory management, which calls for a combination of planning, accuracy, and ongoing observation. Without it, things quickly get out of hand: understocking causes operational disruptions, overstocking depletes budgets, and inefficiencies appear everywhere. You will undoubtedly miss something crucial if you try to juggle while wearing a blindfold. Simplifying these procedures aims to build a system that functions more intelligently rather than more laboriously.

*assetinfinity.com

Role of Manufacturing Analytics in Problem Solving

Improved Decision-Making

Real-time insights from manufacturing analytics help firms stay ahead of the curve by facilitating data-driven decision-making. By using these tools, businesses can take proactive measures to avoid problems before they arise, such as production delays or equipment failures. It functions similarly to a crystal ball but is supported by actual data rather than conjecture. This degree of understanding makes the entire manufacturing process leaner and more dependable by increasing efficiency and decreasing waste and downtime. Being reactive is insufficient in today’s fast-paced world; you also need to be predictive, which manufacturing analytics provides.

Cost Optimization

Manufacturing analytics helps reduce waste and optimize resource usage by identifying inefficiencies, guaranteeing that every dollar and resource is used prudently. You suddenly realize how much space (and money) you’ve been wasting, much like when you clean up a messy room! Significant cost savings, increased profitability, and an all-around more sustainable operation result from this. Additionally, companies can concentrate on growing rather than continuously putting out fires with improved visibility and streamlined procedures. Working smarter, not just harder, is the key in today’s cutthroat market, and manufacturing analytics enables this.

Enhanced Productivity

By transforming raw data into actionable insights, analytics increases overall productivity, streamlines processes, and decreases downtime. For instance, predictive analytics can predict maintenance requirements, assisting companies in preventing those annoying, unforeseen malfunctions and delays that cause everything to go awry. It keeps you ahead of the game, much like a heads-up display for your operations. In addition to keeping everything operating smoothly, this proactive approach lowers repair costs and increases equipment lifespan. In the long run, it’s about creating a system that works seamlessly, saving both time and money while boosting efficiency across the board.

*binarysemantics.com

Industry Insights

Technology breakthroughs, changing consumer demands, and a greater focus on sustainability are all driving the manufacturing sector’s continued rapid evolution. In addition to influencing how companies function, these shifts have an impact on important indicators like industry growth rates and employee pay.

Salary Trends

The manufacturing industry is witnessing impressive growth in earnings:

| Year | Median Gross Hourly Salary | Industry Position |

|---|---|---|

| 2020 | Rs. 219.4 | 2nd Highest |

| 2023 | Rs. 230.9 | Highest Growth |

| 2024 | Rs. 254.2 | Expected to Lead Growth |

The Monster Salary Index (MSI) reported that India’s manufacturing sector had a 9 percent increase in median gross salary over the past three years, making it the second highest-earning sector in the analysis.

Of the eight sectors analyzed, manufacturing was the only one to see a 9 percent increase in the median gross hourly salary, reaching Rs 230.9. This hourly salary is also 5.2 percent higher than India’s overall median gross salary of Rs 219.4 per hour.

*thehindubusinessline

How Jaro Education Helps You Accelerate Your Career

What Sets Jaro Education Apart?

One of the top online learning platforms, Jaro Education, focuses on helping professionals advance their skills and maintain their competitive edge in the labour market. Jaro provides programmes that are adapted to the changing demands of the industry by collaborating with prestigious universities such as IITs and IIMs, guaranteeing that students acquire skills that apply to the future. It’s similar to being able to access the greatest resources and minds directly from the comfort of your own home. Their courses enable professionals to succeed in their careers and confidently take on real-world challenges by fusing academic brilliance with real-world insights.

Key Highlights

- Exclusive Partnerships: Collaborating with top universities on specialised programmes.

- Flexible Learning Options: Designed to help working professionals balance education and careers.

- Industry-Relevant Curriculum: Developed using the latest market research and insights.

Featured Programme: Manufacturing Analytics PG Certification

Jaro Education, in collaboration with IIM Trichy offers a Post Graduate Certificate Programme in Manufacturing Management & Analytics. This exclusive course enables participants to:

- Gain in-depth knowledge of advanced analytics in manufacturing.

- Develop practical skills through hands-on experience with analytics software.

- Access lifelong alumni benefits and networking opportunities with industry experts.

Key Features of this course are:

- Expert IIM faculty guidance.

- Market-driven curriculum.

- Flexible online learning format.

Your Next Step to Success

By increasing productivity, cutting expenses, and promoting innovation, manufacturing analytics is slowly becoming a transforming industry. Professionals who want to succeed in this fast-paced industry need to educate themselves with the right knowledge and tools.

The manufacturing analytics PG certification programme via Jaro Education provides exactly this, along with an ideal setting for upskilling, learning and staying on top of trends. With this course, you will be equipping yourself with all the tools necessary to flourish in this industry.

Frequently Asked Questions

Manufacturing analytics: what is it?

Manufacturing analytics is nothing but the process of taking large data from the manufacturing process, interpreting it in such a way to derive meaningful patterns & applying the data-driven insights & learnings to the processes in order to optimize production, improve efficiency, and reduce costs. It’s like having a behind-the-scenes playbook that helps businesses make smarter decisions and keep everything running like a well-oiled machine.

What are the advantages of supply chain analytics for manufacturing?

Supply chain analytics improves the efficiency of operations by identifying problem areas, optimizing resource allocation, and reducing overall costs. It also empowers businesses to adapt quickly to market demands, making their supply chains all the more resilient and responsive.

What kinds of jobs are available in the manufacturing sector?

There are many roles that the manufacturing industry offers, like production managers, analytics specialists, and supply chain managers. Now, with AI taking over the world, there is a rising demand for professionals who are skilled in AI, automation, or data analytics to lead innovation. With the manufacturing analytics PG certification programme, you improve your chances of landing such roles in your career.

How can Jaro Education help professionals in manufacturing?

Jaro Education has a lot of industry-relevant programmes, like the manufacturing analytics PG certification, which is specially designed for individuals who want to learn about the world of manufacturing analytics and supply chain analytics. This programme has everything relevant to the manufacturing industry today, along with a perfect blend of theoretical and practical knowledge