What is Supply Chain Design in Logistics?

Table of Contents

- jaro education

- 27, August 2023

- 3:00 pm

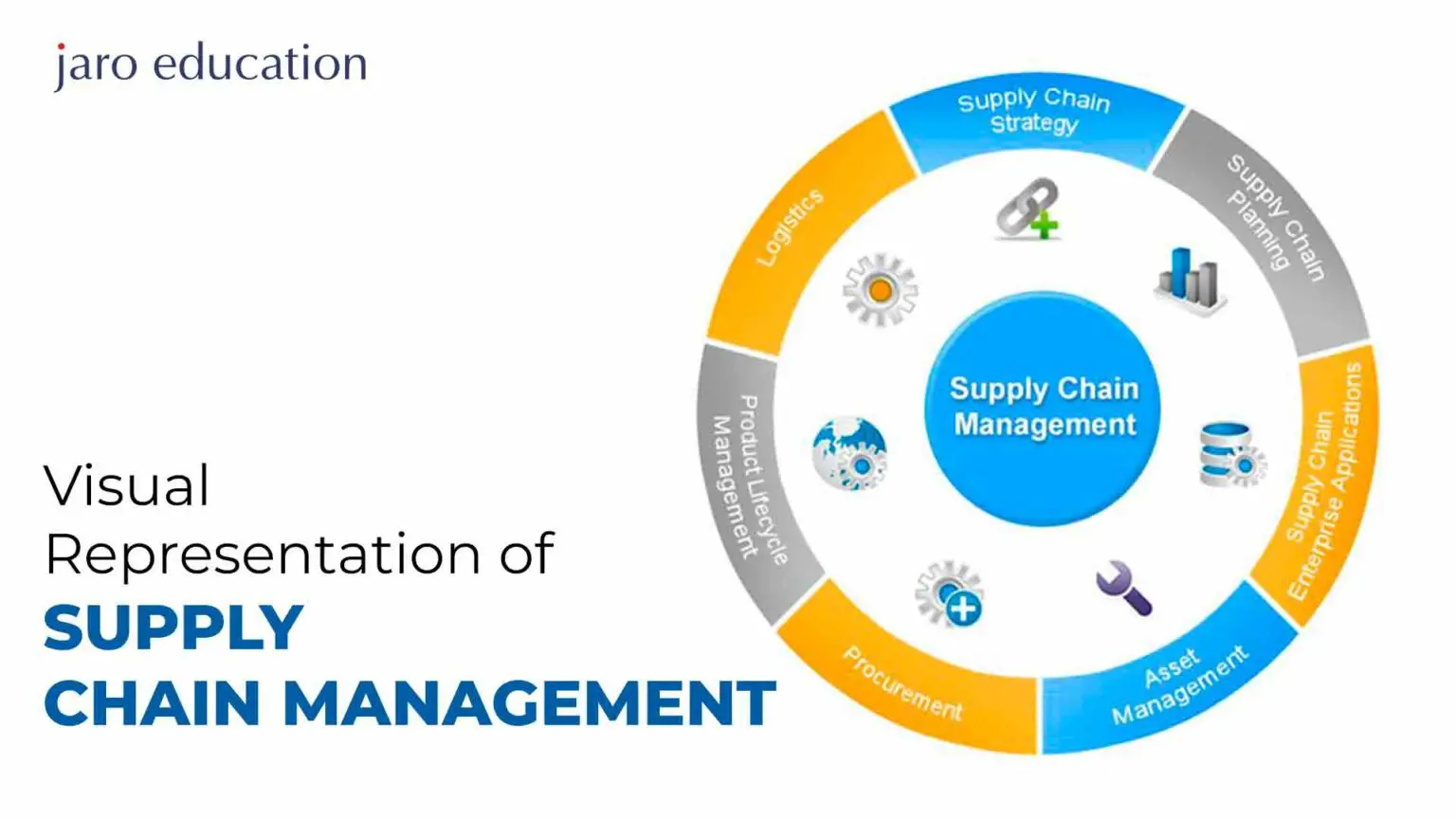

A working model of a supply chain’s structure and network is called a supply chain design. It is used to calculate the time and expense associated with getting products to market. The framework helps an organisation identify errors and possible dangers in the supply chain, and it supports scenario analysis and operational optimisation to save costs, increase customer satisfaction, and accelerate time in the marketplace. Reducing supplies, working capital, and transportation expenses, promoting transparency and finding areas for cost reductions are the main goals of supply chain design.

The IIM Nagpur’s Post Graduate Certificate Programme in Supply Chain Operations & Analytics offers a valuable opportunity for individuals to develop a comprehensive understanding of supply chain design. This training across disciplines is valuable for future professionals and experienced experts working in the production, services, or logistics industries.

What are the Prime Models of the Supply Chain?

Several supply chain modelling options are available. The model a firm chooses will depend on how it is set up and its unique requirements. Here are a few illustrations:

Constant Flow Model

This conventional supply chain model works well for businesses that generate broadly similar items. The goods ought to be highly sought-after and need little to no remodelling. Because of a shortage of variation, supervisors may shorten manufacturing times and maintain strict inventory management. To avoid production delays, managers must routinely refill the supplies in an ongoing framework.

Flexible Model

Businesses that produce items for the seasons or special occasions frequently employ the elastic model. These businesses need long stretches of no or little demand for their products, followed by spikes in demand. With the flexible approach, companies can start production immediately and end it as soon as the market starts to decline. They must accurately predict their need for raw resources, inventory, and labour if they are to be profitable.

Fast Chain Model

This business strategy works best for firms that market their goods in line with current trends. Firms that employ this approach must launch their items fast to capitalise on the current craze. From concept to prototype to manufacturing and, finally, to the consumer, they must move quickly. One sector that makes use of this supply chain paradigm is quick fashion.

Supply Chain Management and Logistics

Supply chain management and logistics are often used interchangeably, but logistics is a crucial component within the broader scope of supply chain management. Logistics specifically focuses on the planning and controlling of the movement, besides the storage of goods, starting from their origin and ending at their final destination. Effective logistics management aims to ensure that there are no delays in delivery at any stage of the supply chain and that products and services arrive in good condition. By achieving this, companies can keep their costs under control and maintain operational efficiency.

How to create the perfect Supply Chain?

Good supply chain management results in effectiveness, reduced expenses, and on-time delivery. All of these are crucial to helping a business reach its financial objectives. For-profit and satisfaction among consumers, the company must develop the ideal supply chain.

Efficiency is the key

Efficiency is a fundamental aspect of an effective supply chain design, aiming to reduce costs and enhance delivery performance. To incorporate efficiency into your supply chain, consider the following steps:

Step 1: Understand the time required for raw materials and finished goods to reach their destinations. This necessitates knowledge about the locations of your suppliers and distributors.

Step 2: Focus on optimising transportation to improve delivery time and reduce costs. Efficient transportation management can lead to satisfied customers more likely to return.

Step 3: Implement automation within your distribution centres to streamline processes, increase efficiency, and lower costs.

Step 4: Utilise modern techniques to enhance the accuracy of demand forecasting. Improved forecasting enables better production planning, enhancing delivery performance and customer satisfaction while reducing costs.

One can ensure that efficiency is ingrained throughout your supply chain by implementing these procedures, resulting in cost savings, increased delivery performance, and ultimately satisfied clients.

Increase supply chain resilience

Increasing supply chain resilience elevates your operational flexibility. One can address any weak points in their supply chain design swiftly or create backup plans. This will save them from later developing into more significant problems. When constructing resilience, one must ensure that the design includes flexibility in inventory capacity and location and adaptation to disturbances.

Adaptability is key in navigating transportation disruptions. When faced with such challenges, exploring alternate routes, such as utilising different ports or transport modes or modifying shipments to mitigate disruptions, is crucial. Strategic inventory positioning is another vital aspect, requiring careful consideration of regular supply and demand dynamics. Flexibility in accessing and utilising inventory becomes essential during fluctuations in demand. Additionally, factoring in weather changes when determining inventory placement can prove advantageous. It is prudent to adjust capacity based on seasonal requirements and carrier availability to address varying capacity needs. Furthermore, ensuring that variable costs align with supply and demand fluctuations enhances operational flexibility in response to changing conditions.

Importance of Simple Supply Chain Design

To ensure an efficient supply chain, it is important to have a simple supply chain design. Here are key significance of simple supply chain design:

- Avoid introducing unnecessary complexity into your supply chain, especially if you have international customers. By keeping the design simple, you can operate efficiently with fewer resources and lower overhead costs.

- Create your supply chain design around the primary volume of goods you will be selling. This approach allows for easier adaptation to changing demands, ensuring flexibility and responsiveness in your operations.

- A simple design facilitates regular audits and continuous improvement efforts. By regularly evaluating and refining your supply chain design, you can identify areas for optimisation and enhance overall efficiency.

- Select your partners carefully, ensuring they are willing to collaborate and work with you during periods of changing demands. Strong partnerships with reliable and adaptable suppliers, distributors, and logistics providers are crucial for maintaining a streamlined and efficient supply chain.

- Optimal supply chain performance requires visibility into the various processes and activities. Simple designs often come with better visibility, enabling you to monitor operations, identify bottlenecks, and make timely adjustments to overcome disruptions or inefficiencies.

Advantages of Creating A Successful Supply Chain

A company’s supply networks play a crucial role in its operation. Creating a successful supply chain will provide several advantages for the company. Here are a few of the key advantages.

- Improved customer satisfaction through faster deliveries enabled by optimised logistics and distribution systems.

- Better inventory management, ensuring timely delivery of goods and accurate demand forecasting.

- Reduced operating costs by locating facilities near suppliers and customers, maintaining optimum stock levels, and efficient delivery planning.

- Cost reduction leads to increased profits.

Takeaway

A supply chain should be carefully built, taking into account all of its components. The function will be designed by knowledgeable supply chain specialists in a way that the clients are happy and the business is profitable. A strong supply chain design also guarantees greater effectiveness and lessens the chance of human error by minimising human interference. After taking a course on the topic offered by reputable universities, it is feasible to produce a quality design.

The Post Graduate Certificate Programme in Supply Chain Operations & Analytics by IIM Nagpur offers useful information about supply chain operations and management and gives students the skills they need to be successful supply chain designers. Enrolling in this course via Jaro Education will enable participants to advance their careers while developing their knowledge of this critical area of supply chain management.